AT A GLANCE

Tottser Tool & Manufacturing offers world-class production of metal stampings and assemblies utilizing low carbon to advanced high strength steel, offering its customers a broad portfolio. Our resources include the following:

- Brackets

- Brake Shields

- Control Arms

- Lighting Fixtures

- Links

- HVAC

- Reinforcements

TOOL & DIE DESIGN

Tottser Tool & Manufacturing has extensive knowledge and experience in the design, feasibility and construction of tools. Our tool and die experience extends from in-die tapping to large and heavy gauge components covering a broad spectrum of materials from aluminum to ultra-high strength steels. Our capabilities include:

- Tool Design and Engineering

- Tool & Die Construction

- Gage Design & Construction

- Forming Feasibility

- Tool Trial and Simulation

- Quality Control

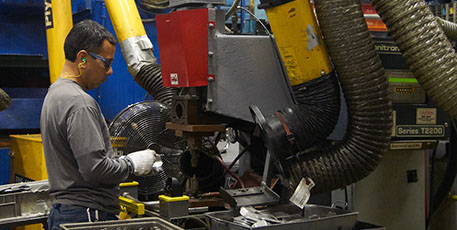

COMPONENTS

We begin with a complete understanding of our customers’ needs and work closely with them to achieve cost-effective solutions that meet the demand for stamped components and assemblies in automotive and specialty customer applications. Solutions include:

- Stamping: 150-400 ton

- Welding: Spot

- In-die Tapping

- Orbital Riveting

- Assembly

- Physical Testing

A REPUTATION FOR QUALITY

Tottser Tool & Manufacturing has a proven track record of meeting deadlines and producing parts per customer specifications. Our Quality team is headed by a manager with years of experience in the industry. We utilize the newest gauges and equipment to ensure accuracy. Our investment in equipment is our investment in your final product. The quality system we have in place guarantees that all facets of the production process, from incoming material to shipment of product, meets or exceeds the required specifications through:

- Control Plans

- Process Flow Chart

- Incoming, First Piece, In-Process, Visual and Final Inspections

- PPAP

- PFMEA

- Gauge R&R Studies

- Capability Studies

- Full Lot Traceability

EQUIPMENT & FACILITIES

At Tottser Tool & Manufacturing, we believe in investing in current technology and state-of-the-art equipment means we can produce high quality parts quickly. Current equipment across all affiliated locations includes:

- 120 stamping presses – ranging from 25 to 3,500 ton

- 150 weld cells including plasma, resistance, MIG, robotic weld stations

- Orbital riveting equipment

- Various equipment including mills, drill presses, CMM’s, wire EDM’s, 5-axis laser, cranes

- Eight U.S. manufacturing locations spanning over 700,000 square feet